views

In the realm of industrial machinery, the significance of bearings cannot be overstated. These essential components are the linchpins of smooth mechanical operations, ensuring reduced friction, precise motion, and prolonged equipment life. As industries push the boundaries of performance and efficiency, the demand for high-quality bearings has surged. AUBEARING has emerged as a leader in this field, offering innovative, durable, and high-performance bearing solutions that cater to a wide range of industrial applications. This article explores AUBEARING’s approach to bearing technology and how it continues to redefine industry standards.

The Vital Role of Bearings in Modern Machinery

Bearings are fundamental to the functionality of numerous mechanical systems, from automotive engines and aerospace components to manufacturing machinery and consumer electronics. Their primary role is to support rotating or moving parts, minimizing friction and wear while facilitating smooth motion. As machinery becomes more complex and operates under increasingly demanding conditions, the performance of bearings becomes a critical factor in overall efficiency and reliability.

AUBEARING understands the pivotal role of bearings in enhancing machinery performance. The company’s commitment to excellence is evident in its approach to designing and manufacturing bearings that meet the highest standards of quality and performance. As a trusted ceramic balls wholesaler, we provide high-quality ceramic balls that meet the rigorous demands of various industries.

AUBEARING’s Commitment to Innovation and Quality

AUBEARING’s reputation as a top bearing manufacturer is built on its unwavering commitment to innovation, quality, and customer satisfaction. The company’s approach encompasses several key aspects that distinguish it from competitors:

1. Cutting-Edge Design and Engineering

AUBEARING’s design philosophy is rooted in advanced engineering and innovation. The company utilizes state-of-the-art computer-aided design (CAD) and simulation tools to create bearings that are optimized for specific applications. This sophisticated design process ensures that each bearing delivers exceptional performance by addressing factors such as load capacity, speed capabilities, and resistance to environmental stressors.

2. Superior Materials for Enhanced Performance

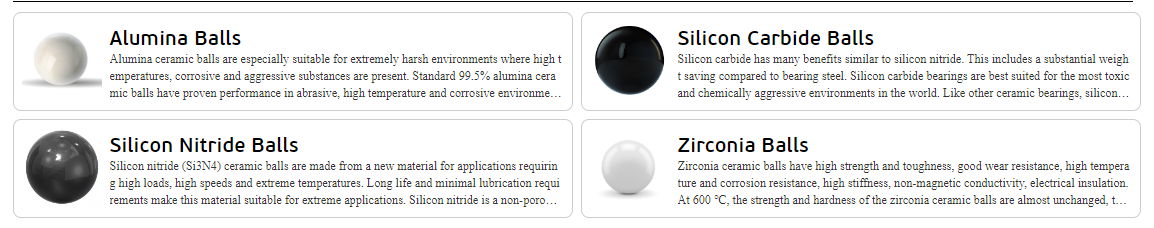

The quality of materials used in bearing production is crucial to their performance and longevity. AUBEARING sources high-grade steels, advanced ceramics, and specialty alloys to produce bearings that offer exceptional durability and reliability. These premium materials are selected for their ability to withstand extreme temperatures, resist corrosion, and handle high loads, ensuring that AUBEARING’s bearings perform consistently in diverse operating conditions.

3. Precision Manufacturing Techniques

AUBEARING’s manufacturing processes are designed to achieve the highest levels of precision and consistency. The company employs advanced machining, grinding, and assembly techniques to produce bearings with tight tolerances and uniform quality. Automated processes and quality control measures ensure that every bearing meets stringent performance standards, contributing to the overall reliability of the machinery in which they are used.

4. Rigorous Testing and Quality Assurance

Quality assurance is a cornerstone of AUBEARING’s operations. Each bearing undergoes a series of rigorous tests to assess its performance under real-world conditions. These tests include load capacity evaluations, speed trials, and environmental stress simulations, allowing AUBEARING to identify and address potential issues before the bearings reach the market. This comprehensive testing process ensures that AUBEARING’s products exceed industry standards for quality and reliability.

AUBEARING’s Diverse Range of Bearing Solutions

AUBEARING offers an extensive range of bearing products designed to meet the needs of various industrial applications. From standard bearings to specialized solutions, AUBEARING’s product portfolio includes:

-

Ball Bearings: Ideal for high-speed applications, AUBEARING’s ball bearings offer low friction and smooth operation, making them suitable for use in electric motors, automotive components, and electronic devices.

-

Roller Bearings: Engineered for heavy-duty applications, AUBEARING’s roller bearings provide superior load-bearing capacity, making them well-suited for industrial machinery, construction equipment, and mining operations.

-

Thrust Bearings: Designed to handle axial loads, AUBEARING’s thrust bearings are commonly used in automotive steering systems, heavy-duty pumps, and turbines, providing reliable support in demanding environments.

-

Spherical Bearings: AUBEARING’s spherical bearings are designed to accommodate misalignment and high loads, making them ideal for applications such as conveyor systems and agricultural machinery.

-

Self-Aligning Bearings: These bearings automatically adjust to correct misalignment, ensuring smooth operation in challenging conditions, such as those found in conveyor systems and industrial equipment.

Why AUBEARING Stands Out in the Bearing Industry

AUBEARING’s success in the bearing industry is attributed to its focus on delivering high-quality, reliable products and exceptional customer service. Here’s why businesses choose AUBEARING:

1. Customized Bearing Solutions

Recognizing that each application has unique requirements, AUBEARING offers customized bearing solutions tailored to specific needs. This bespoke approach ensures that customers receive bearings that are optimized for their particular applications, enhancing performance and reliability.

2. Expert Support and Consultation

AUBEARING’s team of experts provides valuable support throughout the bearing lifecycle, from selection and installation to maintenance and troubleshooting. This hands-on support ensures that customers can maximize the performance and longevity of their bearings.

3. Global Reach and Efficient Distribution

With a robust global distribution network, AUBEARING ensures that its products are readily available to customers around the world. The company’s efficient logistics operations help minimize lead times and support uninterrupted production schedules.

4. Commitment to Sustainability

AUBEARING is dedicated to reducing its environmental impact through sustainable manufacturing practices. By optimizing energy use, minimizing waste, and incorporating eco-friendly materials, AUBEARING supports a more sustainable future for the industry.

Choose AUBEARING for Superior Bearing Solutions

AUBEARING’s dedication to innovation, quality, and customer satisfaction sets it apart as a leader in the bearing industry. Whether you need standard bearings or custom-engineered solutions, AUBEARING has the expertise and technology to meet your needs. For reliable, high-performance bearings that drive industrial success, choose AUBEARING.

For more information, contact AUBEARING:

- Email: info@aubearing.com

- Phone: +86 15006356216

- Address: No. 118, Industrial Park, Yandian Town, Linqing City, Shandong Province, China

AUBEARING—precision, performance, and innovation in every bearing.